Projects

Cargotec - Kalmar

- Mobile development

See how Kalmar Cargotec achieved 103% efficiency gains with a custom mobile app. Read the case study & learn more about the solution that supports 17 languages.

About the company

Kalmar is the global leader in sustainable cargo handling for ports, terminals, distribution centers, and heavy industry. With an extensive electric portfolio and global service network, Kalmar assists clients in transitioning to safer, more environmentally friendly, and efficient operations. Together, they develop innovative solutions that shape the future of the industry, improving customers’ every move.

Kalmar is part of Cargotec. Cargotec's (Nasdaq Helsinki: CGCBV) sales in 2021 totaled approximately EUR 3.3 billion and employs around 11,500 people.

Technologies

React Native

Duration of the project

2020 - 2021

The challenges

Kalmar's solutions handle 1 in 4 containers globally, and their product range includes various equipment like reachstackers, forklift trucks, terminal tractors, empty container handlers, and straddle carriers.

Most of their machines are too big to be transported in one piece, implicating the need for the commissioning process. The commissioning process includes inspection, handover, and invoice. In addition, every segment requires paperwork and data entering into several systems.

Paperwork was handled manually, causing a massive workload and requiring the involvement of numerous stakeholders. The long and manual process could in some cases result in missing information about the issues on a machine when it was delivered, the timing of its assembly and readiness for customer delivery, and the commencement of the warranty period.

To ensure the top-level customer experience, Kalmar needed a trusted partner to digitalize this process. That's where ZenDev came into the picture.

The solution

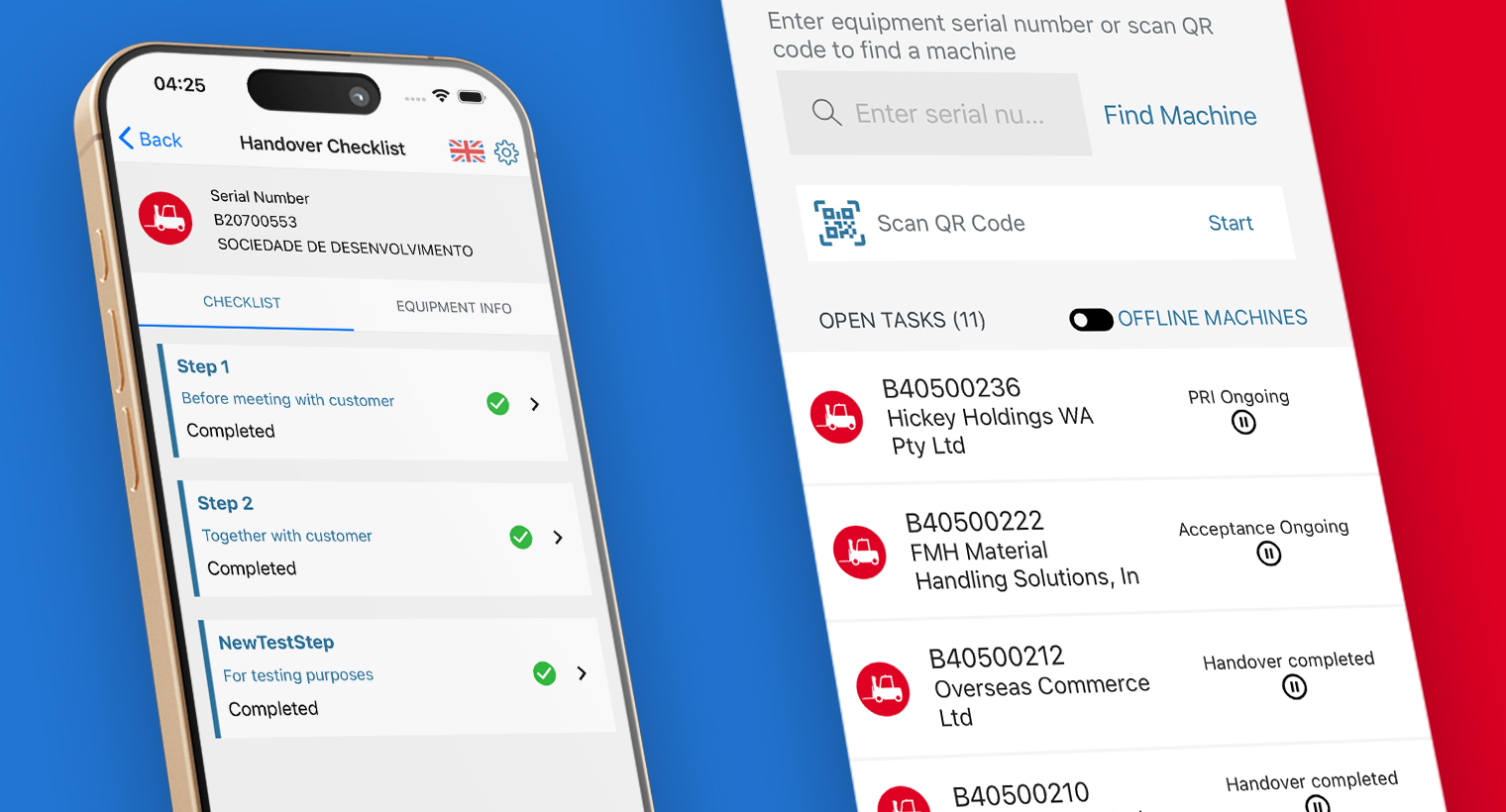

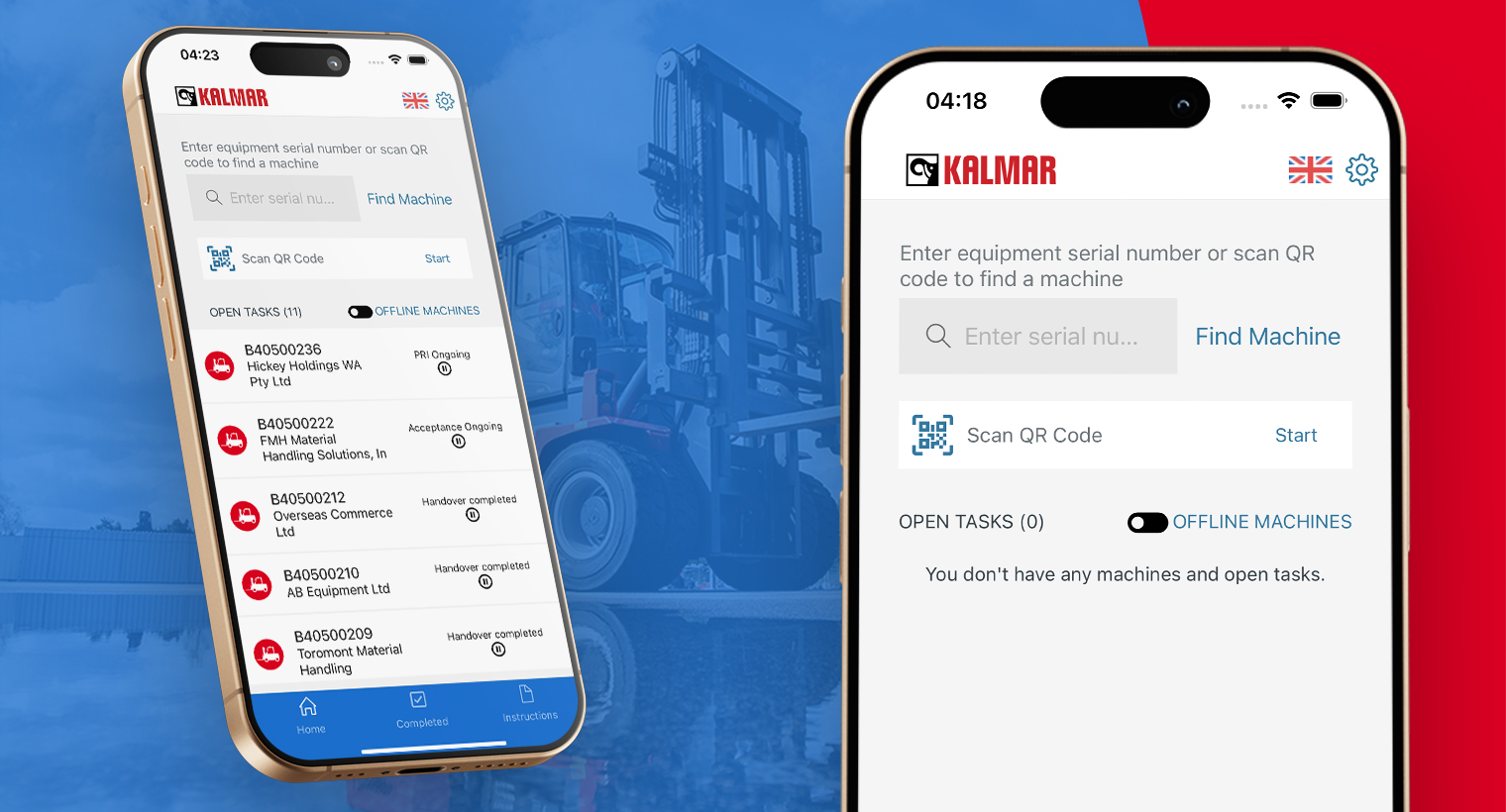

We aimed to enhance Kalmar's customer experience and streamline its business processes. To achieve this goal, ZenDev developed a mobile app that digitalized and automated their workflows. The app resulted in a 103% increase in the efficiency of operations and communication with their customers.

The Kalmar PDT - the Perfect Delivery Tool

Kalmar's technicians and sales representatives utilize this tool during the commissioning process. It provides them with assembly guidance and a PRI - Product Receipt Inspection checklist, which is used for reporting any deviations.

The standardized process in the app has greatly improved the customer experience, ensuring that every customer is treated like a king and receives a machine in perfect condition. This process includes assembly guidance, an inspection checklist, a handover checklist, and digital machine acceptance.

The benefits of the app are numerous. Pictures and written comments are sent directly to the quality teams in the factories, which ensures that future machines will have even higher quality. Digitalization also enables further automation, such as warranty administration and invoice creation.

We ensured the app was user-friendly for all users regardless of their language.

UX designers played an important role and helped us implement support for 17 languages so every user could enjoy the app's full potential without any barriers.

Results

Increased efficiency (103%)

The PDT app was our first big step into the digital world using apps and Cloud solutions. By implementing this app, we could, with one tool, solve multiple issues that we had with our delivery process of new machines to our customers. The PDT app helps us improve the machine quality, shorten our lead time and increase our cash flow.

Anton Sandén

Director QEHS Engineering and Business Intelligence

Overview

Results

Increased efficiency (103%)

Duration of the project

2020 - 2021

Technologies

- React Native

Next in line

We built a platform for facility management with the mindset that everything needed to reside in digital form, in a so-called “digital twin.”