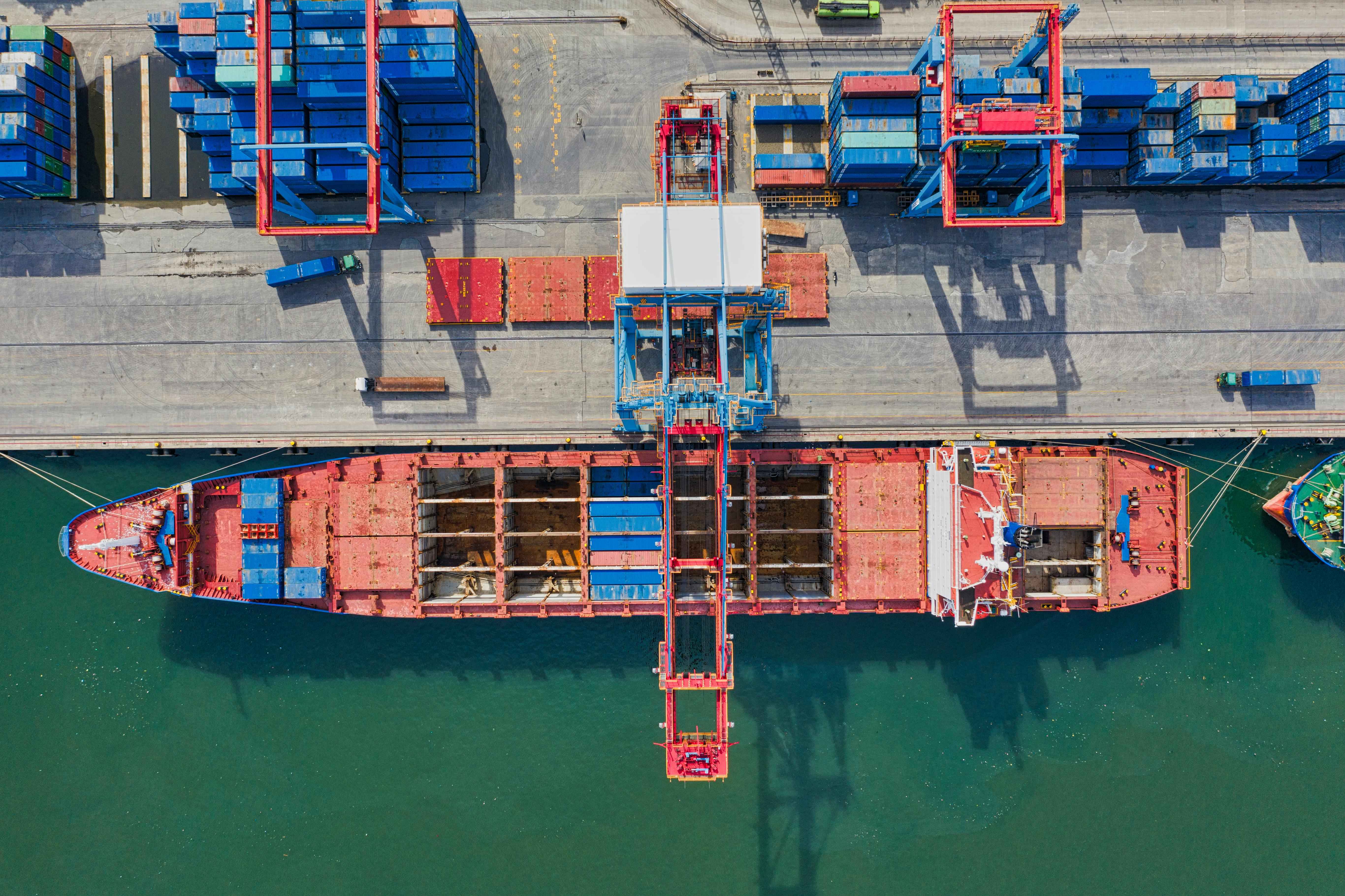

Imagine real-time data flowing effortlessly, optimizing routes, managing inventory and ensuring on-time deliveries.

Sounds unreal? It doesn't have to be.

One of the most effective ways to achieve this is to integrate your existing systems with advanced technology, such as blockchain, artificial intelligence and the Internet of Things. While terms like blockchain, AI, and IoT might seem complex, we'll break down their benefits and applications in simple terms throughout this article.

Let's take a look at some of the biggest challenges facing logistics companies today. We'll address how these issues can impact your business and explore solutions to maximize your operational performance.

- Inefficient manual tasks:

Traditional logistics processes often rely on manual tasks and outdated systems that result in hidden costs. These tasks include data entry in multiple systems, order processing, document management, and scheduling which are often error-prone and time-consuming, leading to delays and decreased productivity.

Potential solution: Artificial intelligence (AI)

AI-powered RPA tools can automate repetitive tasks such as data entry, form filling, and invoice processing. This frees up human workers for more strategic activities like problem-solving and customer interaction. Also, AI in logistics uses machine learning algorithms to analyze vast amounts of data from various sources, including sales history, weather patterns, and sensor readings. This deep analysis can help logistics companies predict demand, optimize routes in real time and manage inventory more efficiently.

In the logistics industry, AI has gained immense popularity. One of the most significant advantages of artificial intelligence is that it can significantly reduce errors and increase accuracy and precision. AI improves efficiency by allowing workers to focus on complex work, but it can also improve customer service by providing instant customer assistance and real-time problem solving.

Example: A logistics company uses AI-powered RPA to automate order processing. The AI system automatically extracts data from customer orders, verifies accuracy, and generates shipping documents, eliminating the need for manual data entry and reducing processing time.

- Lack of integration between existing software

Different software systems create isolated data (silos), making it hard to see the whole supply chain and share information across departments.

Potential solution: API-Based Integration

In logistics, API integration connects a company's internal systems like warehouse and transport systems with external platforms like Enterprise Resource Planning (ERP) systems, freight carriers, and even customs authorities. This creates a seamless flow of data across the entire supply chain.

By connecting systems like warehousing, transportation, ERP, and carriers, APIs create a unified view of the supply chain. This real-time visibility improves inventory and shipment tracking, enabling proactive issue identification. Automating tasks such as loading tenders and invoicing saves time and reduces errors. Moreover, data-driven decision-making, such as informed carrier selection based on real-time spot prices, optimizes transportation costs.

Although there are challenges such as compatibility between different systems and APIs, the benefits of improved efficiency, enhanced visibility, cost reduction, and competitive advantage make API integration a critical success factor for modern enterprises.

Example: When a customer places an order, the company's internal system (e.g., Warehouse Management System) automatically sends the shipment details (origin, destination, weight) through an API to a freight marketplace platform.

- Non-optimized routes and tracking: Inefficient routes lead to wasted time and fuel, while poor tracking can cause delayed shipments and unsatisfied customers.

Potential solution: The Internet of Things (IoT)

IoT in Logistics goes beyond simple GPS trackers and Bluetooth. It's a network of intelligent devices – sensors, cameras, RFID tags – embedded throughout the supply chain, creating a connected ecosystem.

Sensors and RFID tags provide a wealth of real-time data on location, temperature, potential problems, and more. This real-time data, collected from sensors, GPS devices, and various monitoring systems, provides useful insights into supply chain visibility, guarantees product quality and keeps your customers informed.

It provides constant updates on product location, allowing businesses to optimize routes, prevent delays, and quickly respond to issues. Time is saved by choosing the best possible route, and real-time updates allow drivers to avoid traffic jams, reducing fuel consumption.

Beyond operational efficiency, IoT drives customer satisfaction through timely delivery updates and transparent communication.

By anticipating potential disruptions and proactively addressing customer concerns, businesses can build trust and loyalty. The predictive capabilities of IoT, derived from historical and real-time data analysis, help companies anticipate future needs, optimize resource allocation, and reduce costs by identifying trends and patterns.

Example: A logistics company transporting temperature-sensitive pharmaceuticals utilizes IoT sensors in its refrigerated trucks. These sensors monitor temperature and humidity throughout the journey. If a sensor detects a temperature fluctuation outside the acceptable range, it can trigger an alert, allowing the company to take immediate action to protect the cargo. This not only ensures product quality but also avoids potential financial losses and reputational damage.

- Lack of data insight and forecasting: Without proper data analysis, it's difficult to predict demand patterns, identify seasonal fluctuations, and optimize inventory level. This can consequently lead to shortages or excess inventory, both of which affect profitability.

Potential solution: Business intelligence (BI) tools

BI enables companies to analyze data, identify trends and make data-driven decisions about inventory management and logistics planning. It helps transform the large amount of data generated by your business into visual reports and dashboards that include charts, graphs, charts and more

BI transforms raw data into actionable insights. By visualizing complex information into user-friendly dashboards and reports, BI uncovers trends, patterns and opportunities. This enables companies to make informed decisions about inventory, logistics and overall operations. From identifying periods of peak demand to optimizing resource allocation, BI provides a clear roadmap for success.

Example: Delays in transportation due to traffic, weather conditions, or logistical errors can lead to late deliveries, impacting customer satisfaction and inventory management. By analyzing past delays, BI examines traffic patterns, weather conditions, driver performance, and even package size. This helps uncover the root causes of delays allowing you to make more accurate delivery time estimates.

- Ensuring Transparency and Security

Modern supply chains often span continents, involving numerous companies and processes. This complexity creates challenges in ensuring both transparency and security

Solution: Blockchain technology

Using Blockchain technology in supply chain management is the best way to track goods, ensuring transparency and security throughout the entire journey. With blockchain, everyone involved in the supply chain can see a clear and unchangeable record of where everything goes, making it easy for everyone involved to track products in the supply chain. This technology is particularly useful for authenticating goods, tracking product origins and ensuring compliance with regulations and standards.

However, the potential of blockchain extends much further; it automates tasks with smart contracts, streamlines processes, and verifies the ethical sourcing of materials.

Blockchain is transforming the logistics and transportation industry. By creating a digital record of everything that happens with the product, it makes tracking simple and secure. This means less paperwork, faster processes and lower costs. Plus, blockchain helps prevent fraud and damage, ensuring products arrive safely and as expected making the whole process easier and more reliable.

Example: Blockchain goes beyond just location and temperature tracking of perishable goods throughout the supply chain. It can verify the authenticity of drugs, like in pharmaceuticals, and ensure ethical sourcing of materials, as in the clothing industry. Blockchain can track its entire journey, from the cotton field to the factory, giving consumers more information and supporting brands that prioritize sustainability.

Why is ZenDev the right partner for you?

Our proven results with clients such as Cargotec and other clients in the logistics industry speak for themselves. Seamless data flow between systems eliminates manual work and Excel headaches, leading to increased efficiency and smooth supply chain operations.

Ready to take your business to the next level with digital transformation? Our team is here to help and guide you every step of the way, providing exceptional support and guidance throughout the process.

Our cost-effective approach, combined with our expertise in technology and project management, ensures that you get the most value for your investment. You have the freedom to adapt and grow with our scalable solutions, knowing your data is secure and your business is positioned for success.

The outcome? Increased productivity, improved accuracy, and significant long-term cost savings.

Would you like to learn more? Book a call with our experts, and we will walk you through our discovery process after we get to know your unique logistics challenges. Together, we'll define a tailored solution that streamlines your workflow, improves efficiency, and drives growth. Additionally, learn more about our approach in our article on "How we work".